U Beam Triangle Kit-A High-Efficiency Stable Solar Mounting

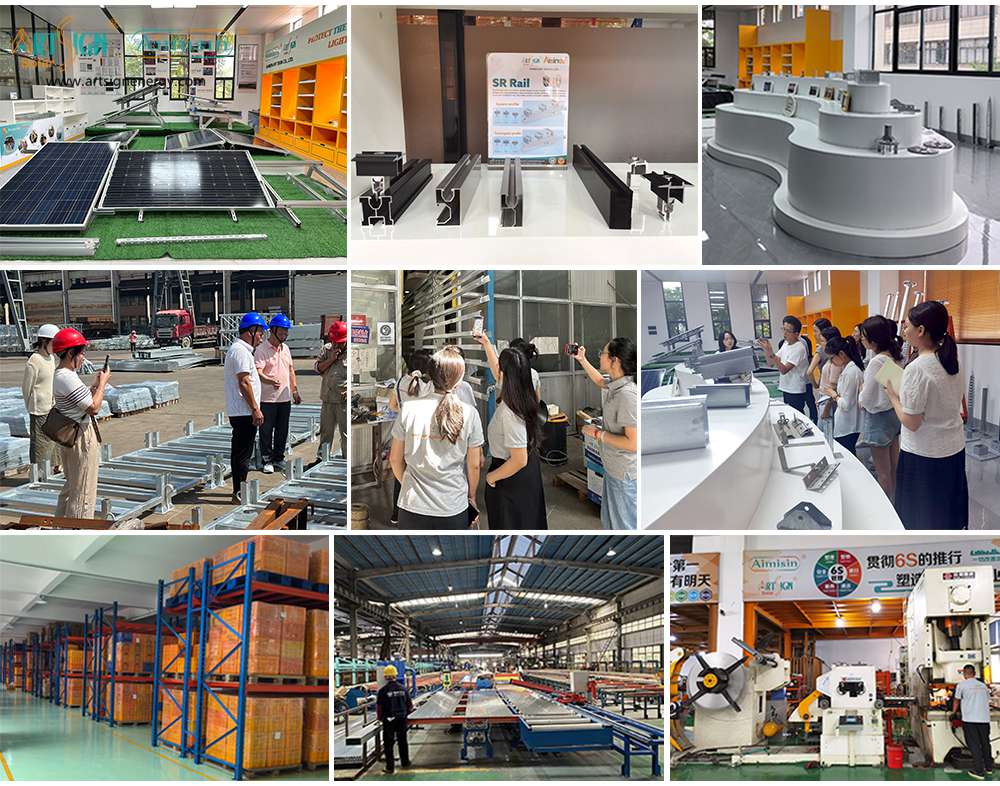

With the rapid growth of global renewable energy, the demand for photovoltaic (PV) solar power systems continues to rise. The choice of mounting structures is crucial in PV system installation, as it directly impacts system stability, installation efficiency, and lifespan. Art Sign Solar Mounting Structure U Beam Triangle Kit has emerged as a highly efficient, stable, and durable installation solution, making it the preferred choice for many PV projects.

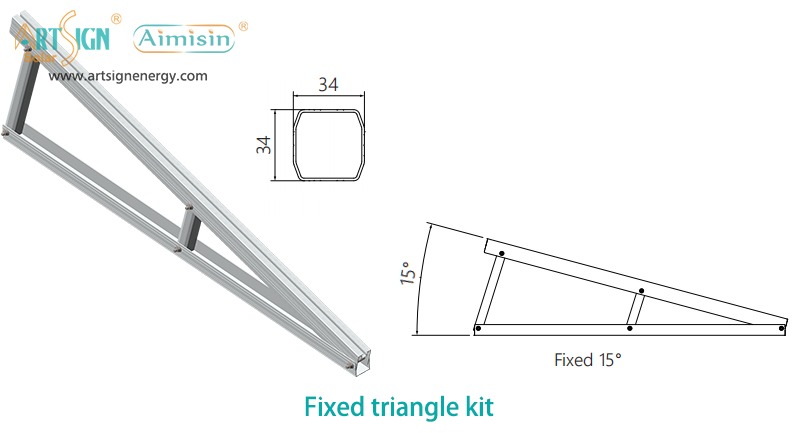

What is a Art Sign U Beam Triangle Kit?

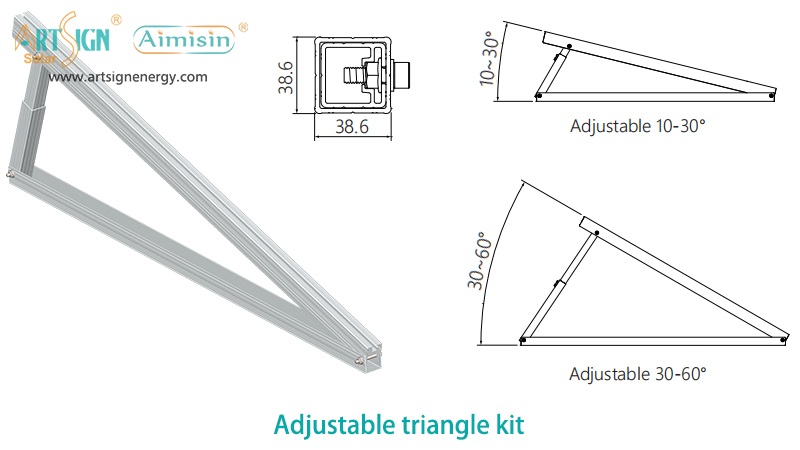

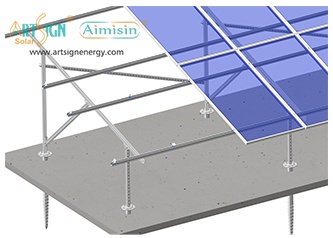

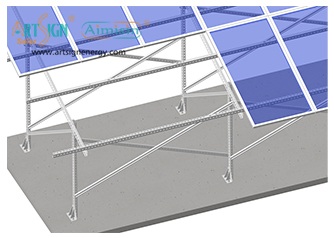

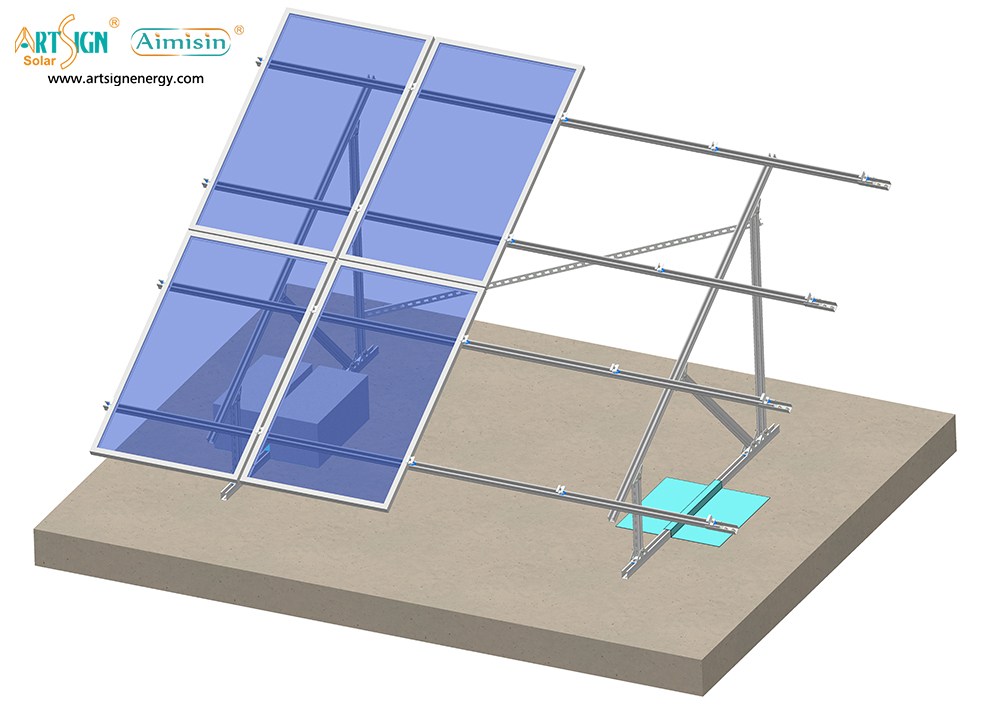

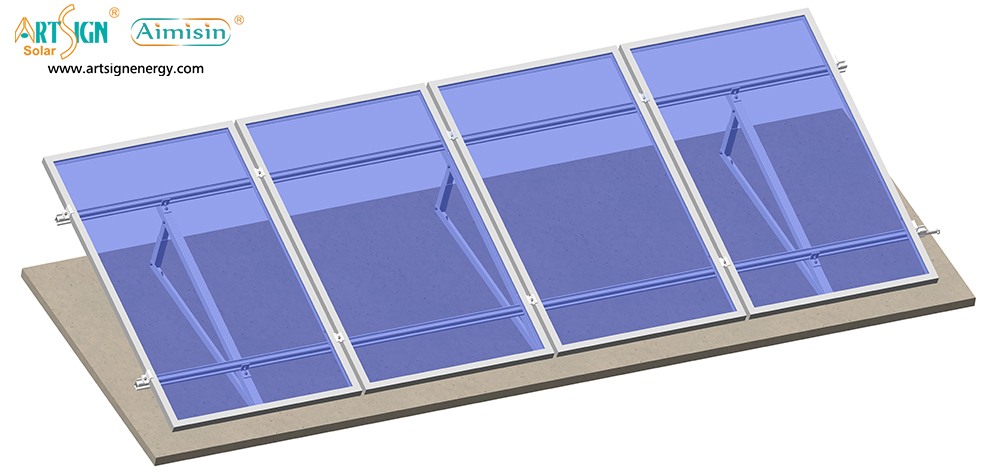

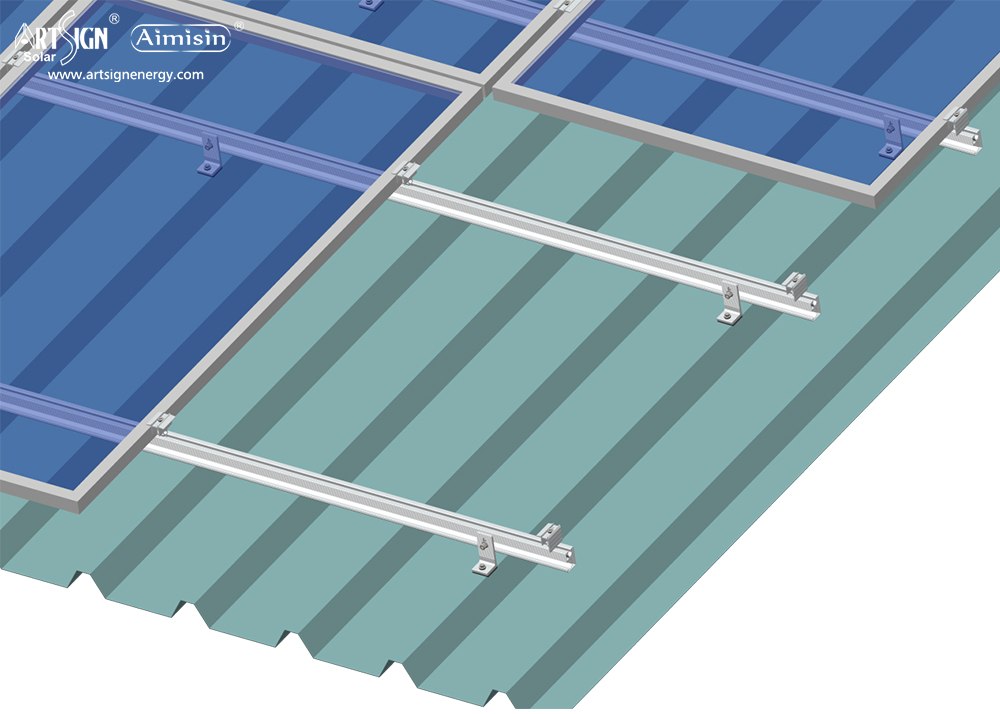

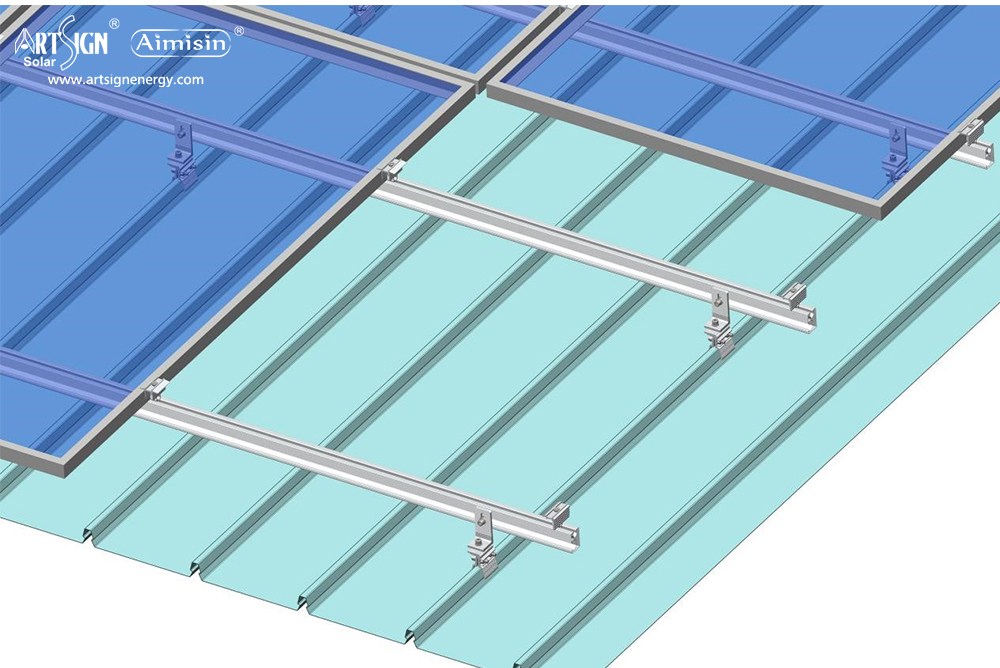

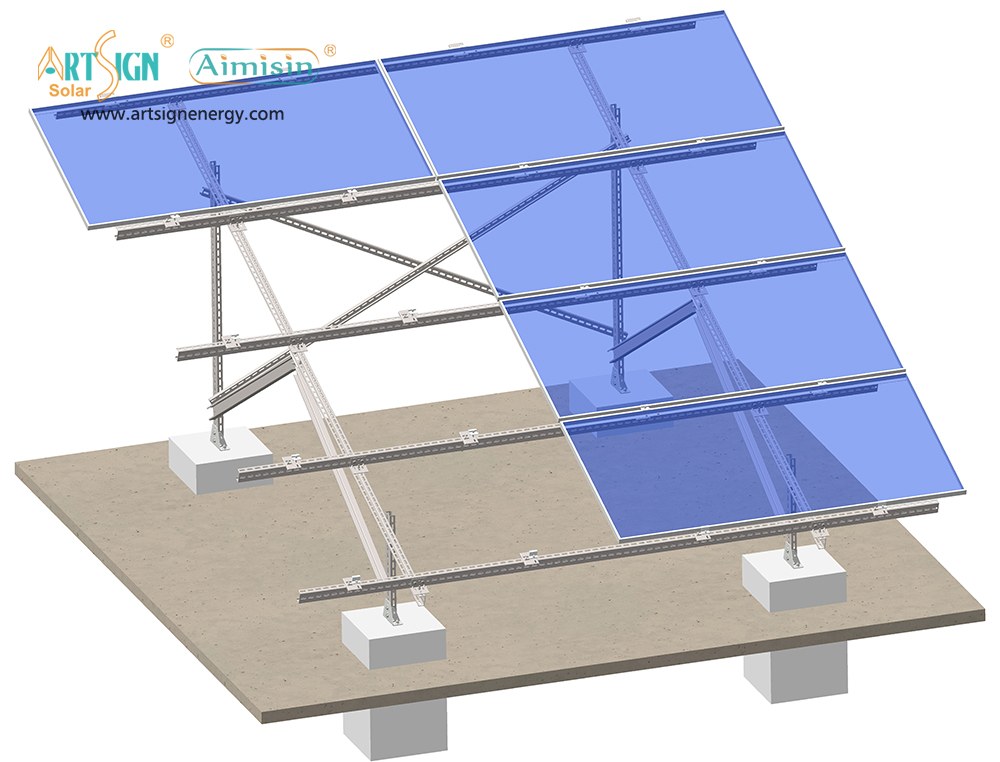

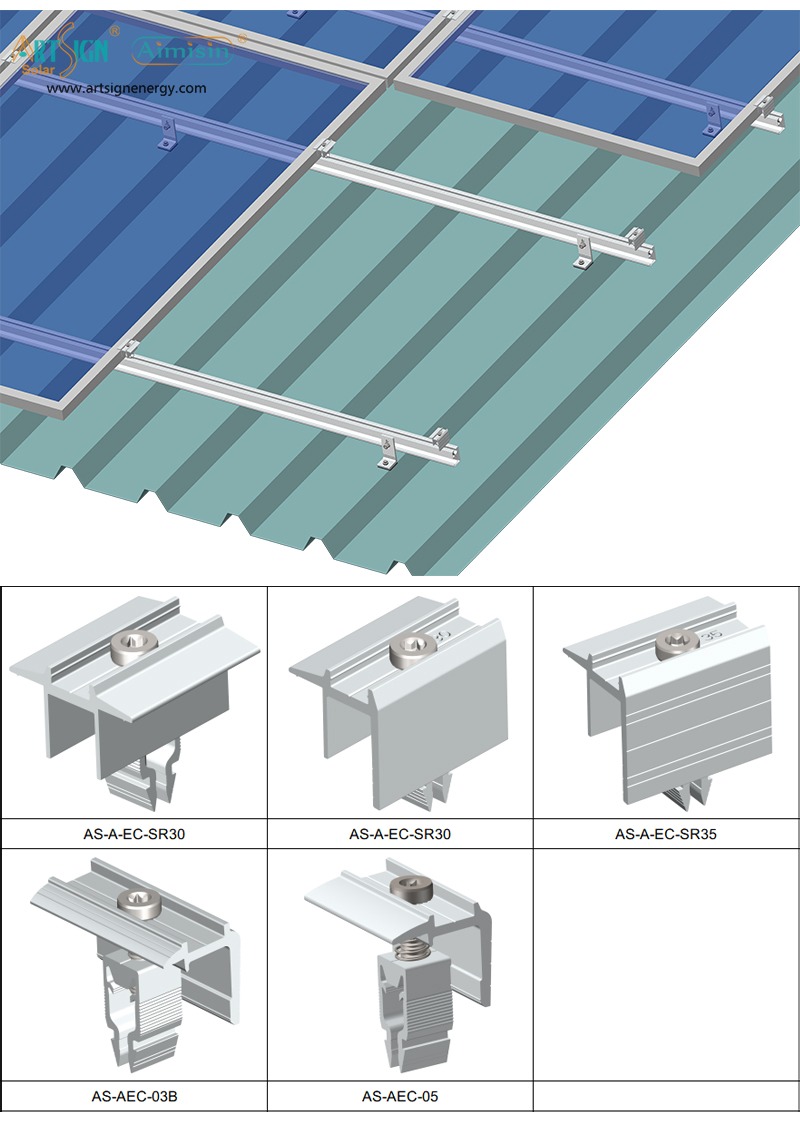

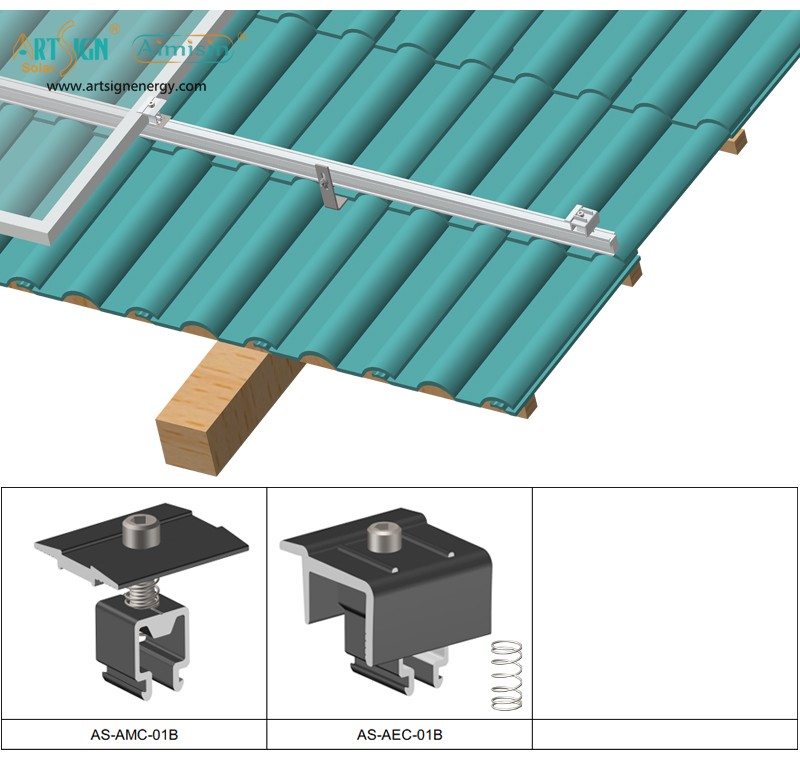

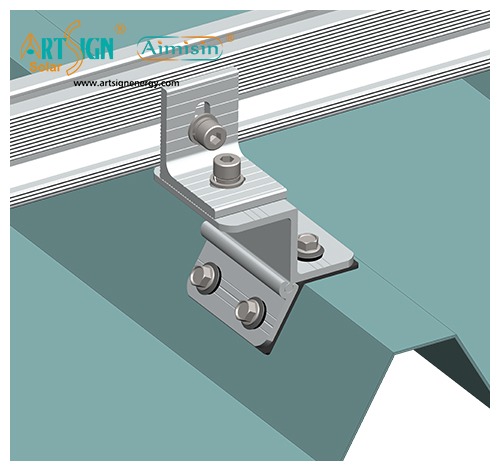

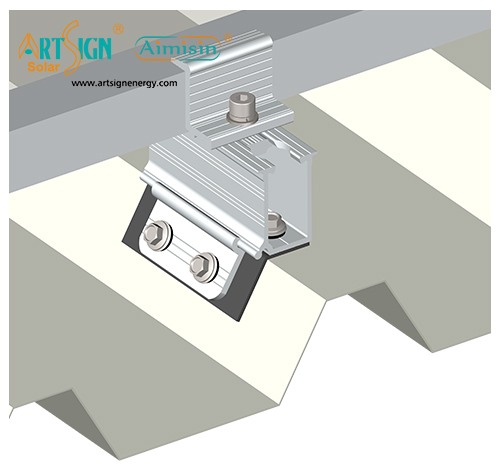

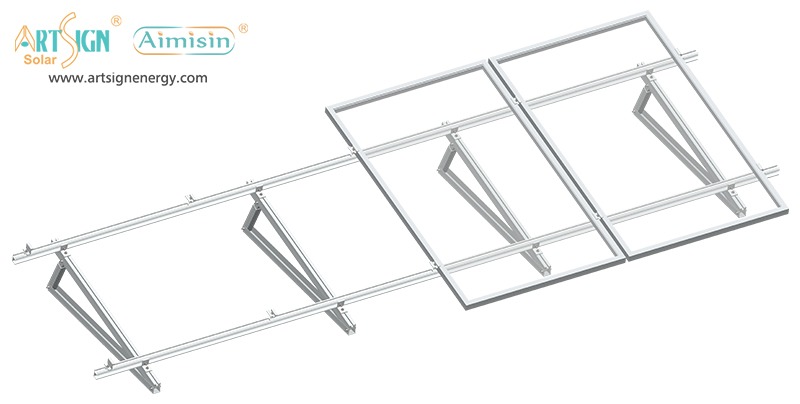

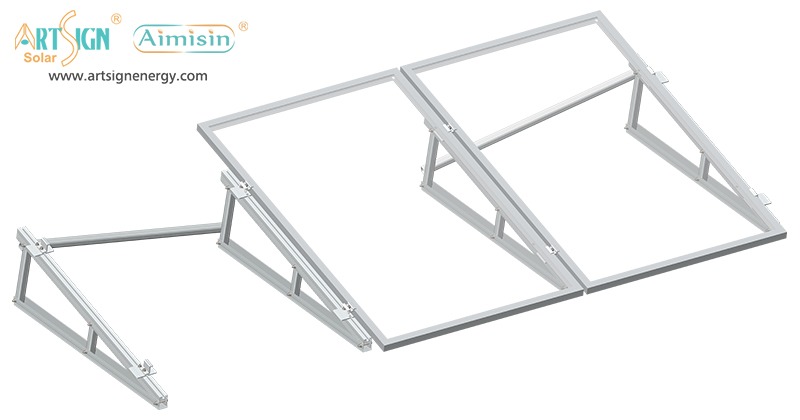

The Art Sign U Beam Triangle Kit is a solar mounting system designed with a U-shaped beam structure and a triangular support frame. It is suitable for flat roof, ground-mounted installations, and certain sloped roof applications, offering stability, easy installation, and durability.

Key Features and Advantages

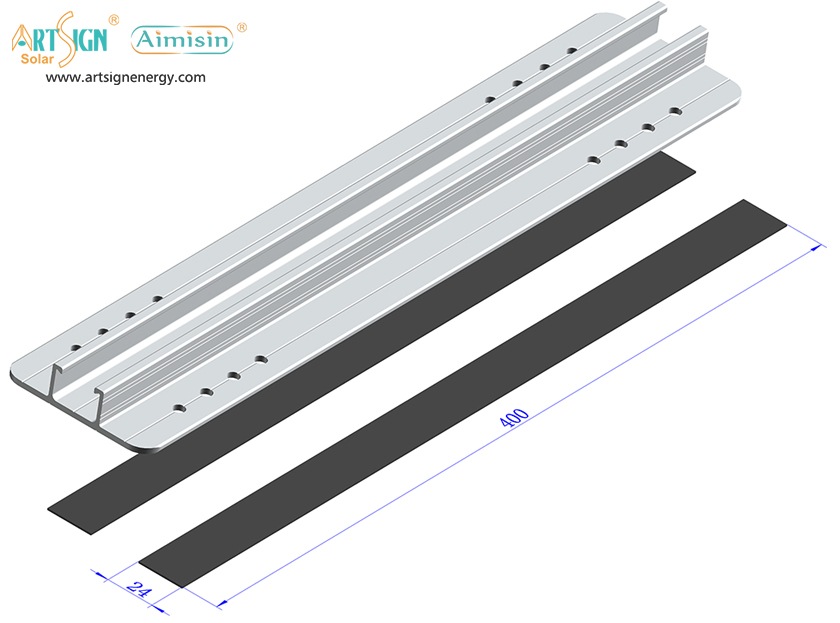

1. High Strength and Durability

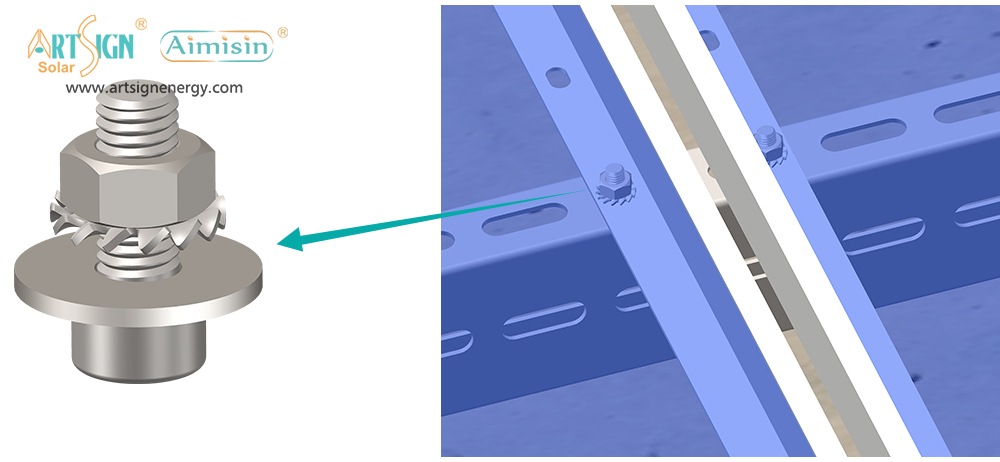

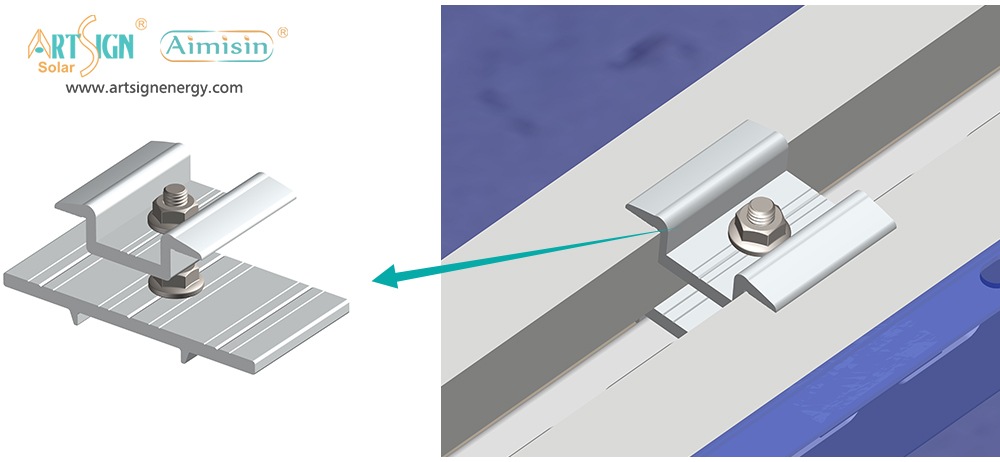

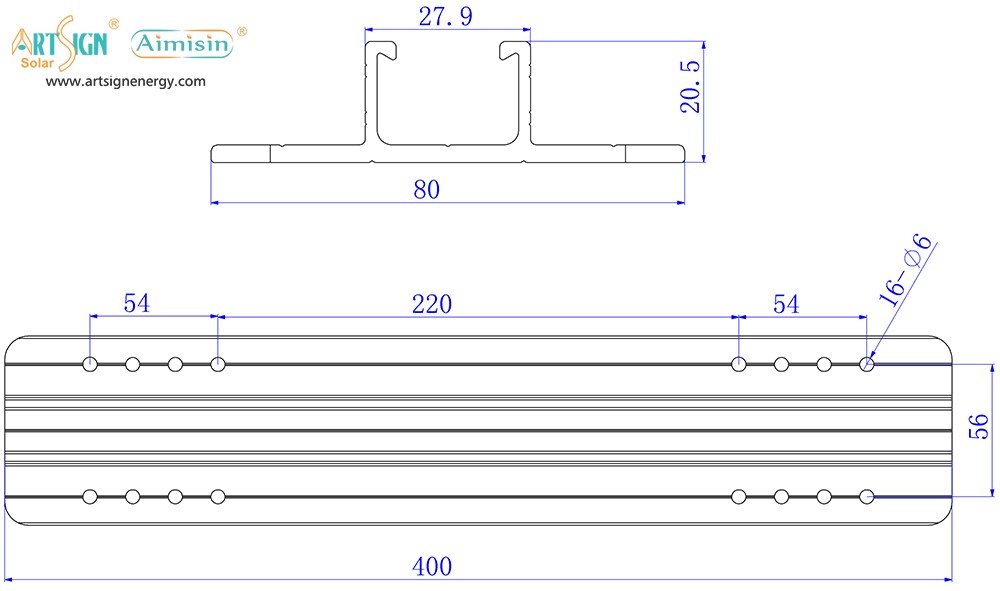

The U Beam Triangle Kit is made of Al 6005-T5.The materials used undergo 10μm thickness anodized aluminum, stainless steel 304 bolts and nuts,effectively protecting the system against moisture, salt fog, and other corrosive elements, ensuring a long service life. It can withstand extreme weather conditions and maintain long-term structural stability for solar panels.

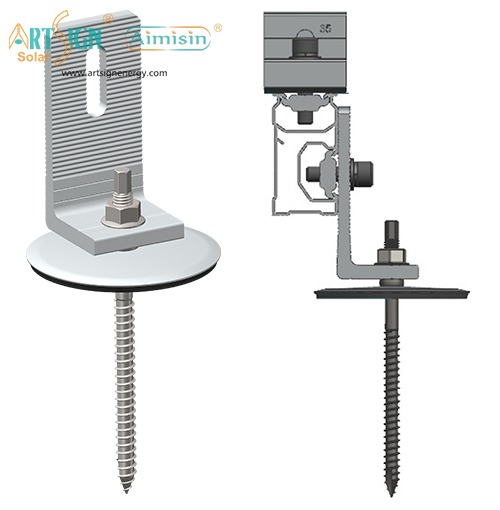

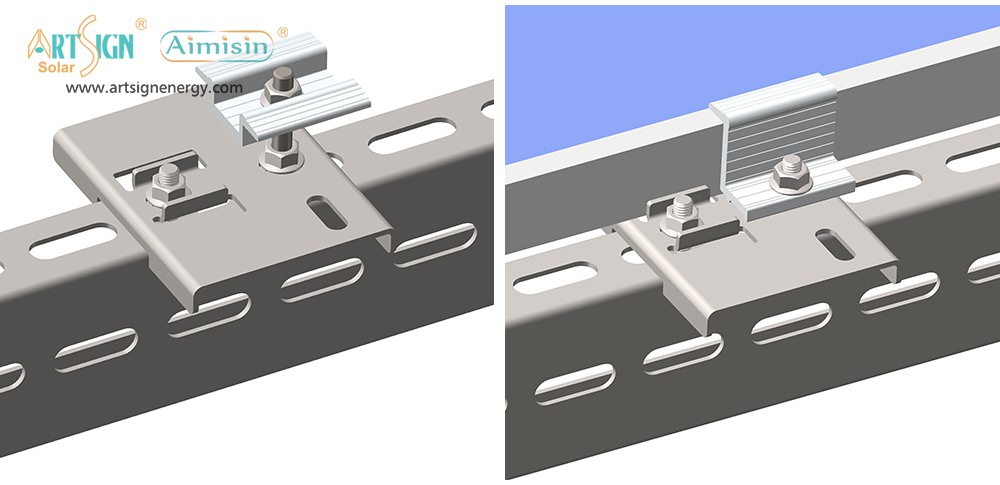

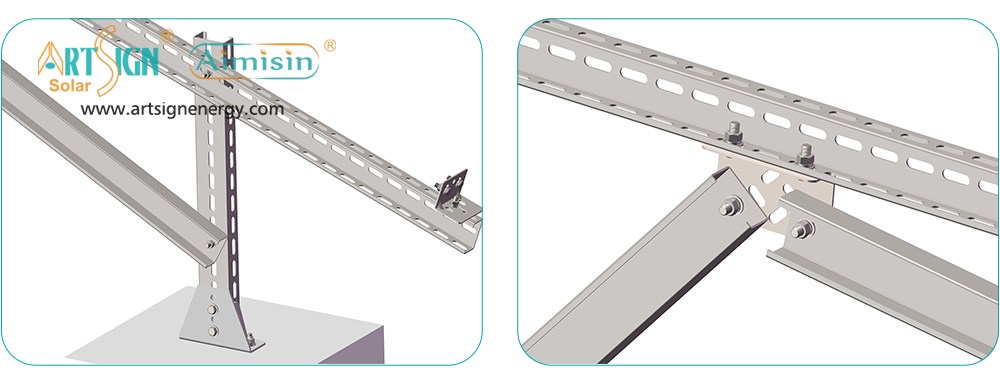

2. Modular Design for Easy Installation

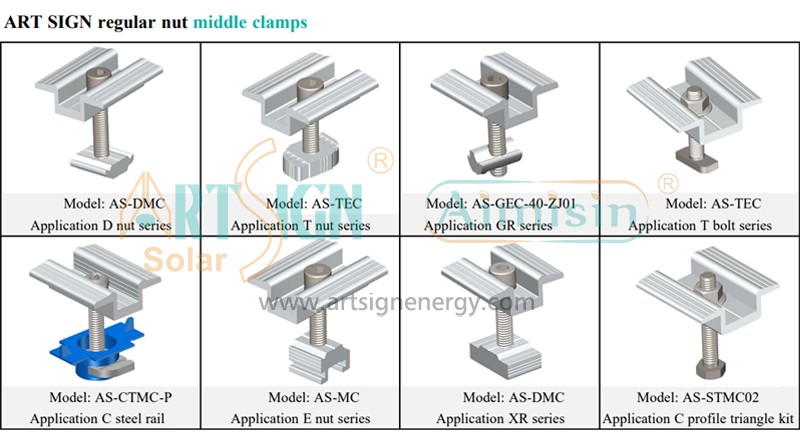

With a pre-assembled modular design, all components come pre-fabricated, eliminating the need for on-site welding. The simple bolt-connection mechanism allows for fast and efficient installation, reducing both time and labor costs.

3. Adjustable Tilt Angles

The triangular support structure can be adjusted to various tilt angles (Fixed customized degree or adjustable 10~30° 30~60°design) based on project requirements, optimizing solar panel orientation for maximum energy efficiency.

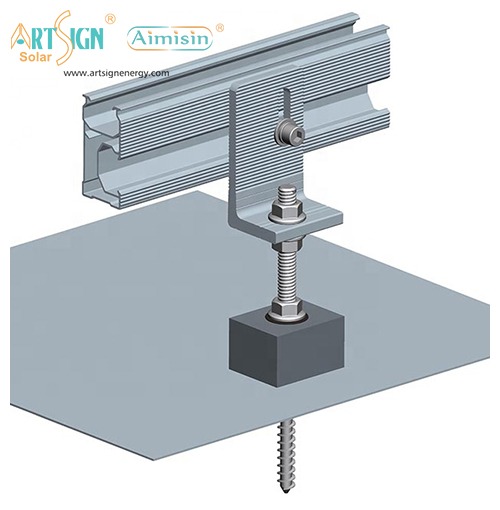

4. Suitable for Various Installation Environments

Whether for flat roofs, concrete rooftops, or ground-mounted PV stations, the U Beam Triangle Kit provides a stable support structure. It is compatible with different anchoring methods, including concrete foundations or ground screws.

Application Scenarios

Commercial and industrial rooftop PV systems

Residential rooftop solar installations

Ground-mounted solar farms

Agricultural photovoltaic (Agri-PV) applications

Off-grid solar mounting systems

Why Choose the Art Sign U Beam Triangle Kit?

Among the many solar mounting solution available, the U Beam Triangle Kit stands out due to its structural stability, quick installation, and cost-effectiveness. Whether for large-scale commercial solar farms or small residential solar projects, this mounting kit provides high-efficiency, safety, and reliability, contributing to the global adoption of clean energy.

If you are looking for a high-quality, cost-effective solar mounting solution, the Solar Mounting Structure U Beam Triangle Kit is your ideal choice.

Contact Us

Feel free to contact us for more details and customized solutions!

Email: sales@artsign.net.cn, Whatsapp / Wechat Skype: +86 18030235875, thanks.